Annealing metal is one of basic and frequent practices of metalsmithing. I am usually working with non-ferrous metals such as silver, copper and brass and frequently annealing them. A very important point is that while you are working with these metals, you are work hardening them. For example, when you are shaping and forming metal, doming, folding or chasing, metal gets gradually harder and harder until you cannot shape or bend it any more. Usually alloys like brass and sterling silver are hardened faster. After work hardening the metal, you can anneal it again and start over, as annealing makes the metal soft.

It is also important to anneal the metal before soldering. Of course you need to clean the metal after annealing if you want to solder it, because annealing metal forms oxides on its surface and these oxides inhibit flux and solder to flow. Therefore, do not forget to clean metal after annealing using pickle.

Before enameling, also I am annealing metal. You might not need it if you do not dome your metal, but if you are working with silver and copper, you usually need to dome to avoid warpage of the metal during the process of enameling. One important application of annealing is when you are using sterling silver for enamelling or keum boo. In these cases you need to depletion guild the metal, meaning anneal sterling silver several times to bring fine silver to the surface and remove other impurities. Of course you will need to pickle and clean the metal between two annealing.

Besides, if you are working with non-annealed thin wire or sheet, there is a chance to break them as they are brittle. However, annealing make them more flexible and workable.

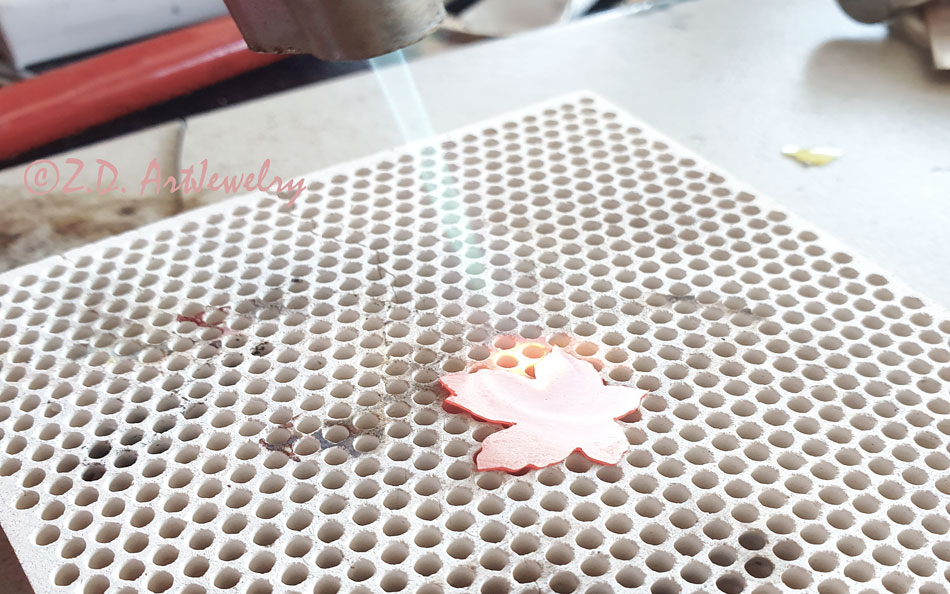

A dull red colour is being known as the sign of annealing metals like sterling silver and copper. So just put the metal on soldering block and use your torch for heating until you see that red colour. If you are using higher gauges of metal either as wire or sheet, stop heating if the metal gets close to annealing but you are not sure about it, and check the metal before heating it further, because your metal piece might melt. I have melted few sterling silver pieces myself! Also it will be better if you use a smaller torch for these metal pieces.

You can draw something using a permanent marker on metal surface and when it gets disappeared during heating, you know that metal is getting very close to its annealing point. Then, quench it in water.

I suggest you have a look on this article about annealing too.

Wish you the greatest time while creating!

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

Stripe is a payment processing platform that enables businesses to accept online payments securely and efficiently.

Service URL: stripe.com (opens in a new window)

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

You can find more information in our Privacy Policy.