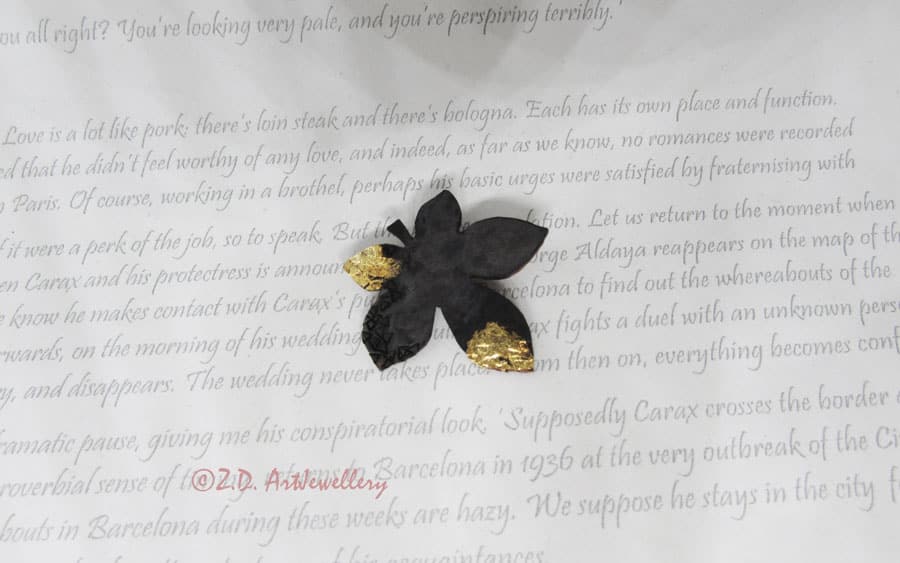

I am using keum boo technique to attach gold foil on silver for awhile and in this post, I want to write about the results I got by trying keum boo in copper. I have written about keum boo and its basis here. Like what I showed and explained in this video, I am using enamelling foils that are thinner than keum boo foils. So, I do not expect well-defined edges and accurate shape. I want to just make an impression! As copper oxidizes fast, you need to try to reduce the time of heating the metal. So, I do not complicate the design and press all the pieces in one step. Then, I usually apply the second layer and finish it. Second layer is required as I am using thin foils. If you use keum boo foils, you wouldn’t need the second layer. I have also made a short video to show how I am adding gold foil to copper.

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

Stripe is a payment processing platform that enables businesses to accept online payments securely and efficiently.

Service URL: stripe.com (opens in a new window)

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

You can find more information in our Privacy Policy.